- PRODUCT DETAIL

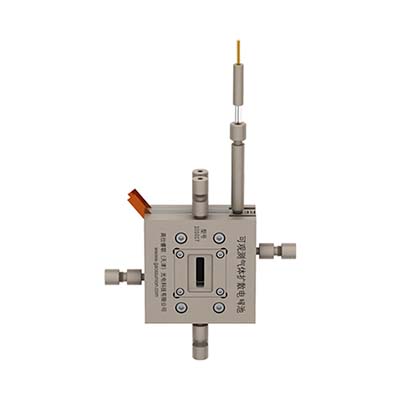

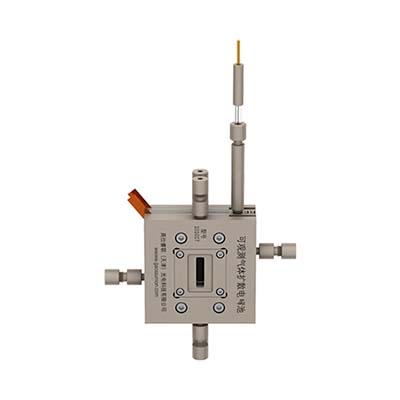

Product Model: 101017

Cavity size: 20*5*3mm

Cathode and anode: carbon cloth & carbon paper (purchase separately)

Reference electrode: silver silver chloride (standard) mercury mercury oxide (purchased separately)

Liquid return cell : to be purchased separately

|

Chemicals. Tin (II) chloride (SnCl2, 99%), bismuth (III) iodide (BiI3, 99.9%), bismuth (III) bromide (BiBr3, 99.9%), bismuth (III) chloride (BiCl3, 99.9%), and hexacarbonyl tungsten (W(CO)6, 97%) were purchased from Alfa Aesar. Hexamethyldisilazane(HMDS, 99%) was purchased from Sigma-Aldrich. Oleylamine (OAm, 70%) and 1-octadecene (ODE, 90%) were purchased from Sigma-Aldrich, and were degassed under vacuum for 1 h at 120 °C prior to use. N-hexane (>97%) and ethanol (>99.7%) were purchased from Shanghai Lingfeng Chemical Reagent Co., Ltd. Commercial Bi (50 nm,99.9%) was purchased from Shanghai BoWei Applied Material Technology Co., Ltd.Synthesis of Sn nanoparticles (NPs). According to a reported procedure,[1] W(CO)6 (10 mg) was added into a three-neck round-bottom flask equipped with a condenser, thermometer adapter, thermometer, and rubber septum. Then, this round-bottom flask was degassed under vacuum at room temperature for 1 h. SnCl2 (40 mg) was dissolved into 1 mL of OAm and 9 mL of ODE by sonication. Then, this mixed solution and 0.75 mL of HMDS were injected into the three-neck round-bottom flask under argon flow.The mixture was heated to 210 °C (~20 °C/min) from room temperature and held for 10 min. The detailed reaction phenomena are illustrated in Figure S3. The flask was quickly cooled by an ice water bath, after which a black solution was obtained. Hexane (12.5 mL) and ethanol (25 mL) were added into the solution to precipitate the NPs by centrifugation at 4000 rpm for 5 min. The precipitate was further purified three times using a hexane/ethanol mixture with a volumetric ratio of 1:1, and finally dissolved into hexane for further characterizations. Synthesis of Sn1-xBix alloy NPs. The same procedure as for Sn NPs was followed by using SnCl2 and BiI3 as precursors. By increasing the amount of BiI3 (2, 5, and 10 mg), a series of Sn1-xBix alloy NPs (Sn0.93Bi0.07, Sn0.86Bi0.14 and Sn0.80Bi0.20, respectively)were obtained. The detailed reaction phenomena are illustrated in Figure S3. Ligand removal. The 10 mg of as-prepared Sn and Sn1-xBix alloy NPs was dispersed in 10 mL of n-butylamine and stirred for at least 12 h. This mixture was separated and purified several times by adding 10 mL of hexane with centrifugation at 4000 rpm for5 min. Finally, NP powders were obtained by drying under vacuum at 60 °C for at least 1 h. |

CHARACTERIZATIONS SECTION

X-ray diffraction (XRD). XRD patterns were recorded on a Rigaku Smart Lab instrument calibrated with Si standard and equipped with Cu Kα radiation (λ = 0.15418 nm) operating at 45 kV and 20 mA. The step size of the measurements was 0.02° in the 2θ range of 10–90°. The obtained data were compared to the Powder Diffraction Files (PDFs) from the International Center for Diffraction Data database (PDF#04-0673

tetragonal Sn). The Williamson-Hall analysis and Scherrer equation were employed to estimate the crystallite size of the NPs by fitting the (200) reflection and applying Jade 6.0 software (Figure S10 and Table S1).

Transmission and scanning transmission electron microscopy (TEM/STEM).